Screen Faster

Screen Faster

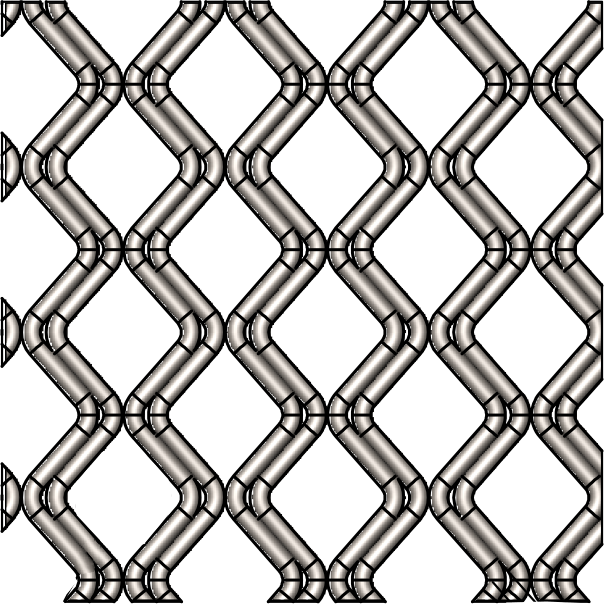

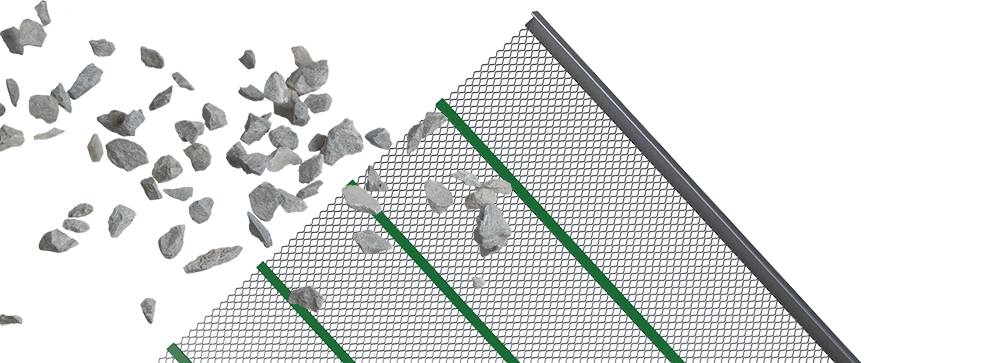

The MAX Kleen™ style self cleaning screen is often described as a speed screen for a reason. Because of the independently attached crimped wire design, each wire is free to vibrate individually, multiplying the overall vibrational frequency of the screen for faster and more efficient material stratification than woven wire screens can achieve. And, when you work with Samscreen to supply your replacement screens, your screens will be delivered faster too – faster than any other supplier in the industry by a wide margin!

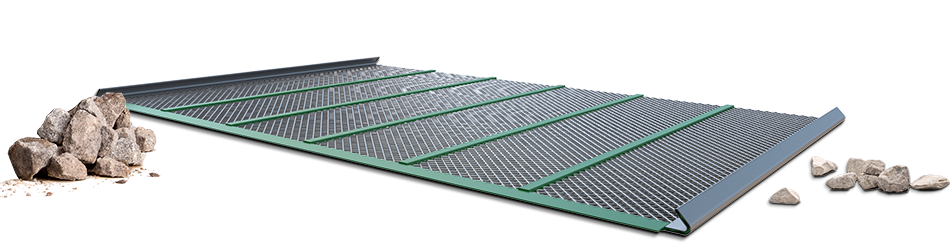

Get more material on the ground FASTER! MAX Kleen screens are designed with independently attached wires that vibrate at a higher frequency than woven wire – efficiently stratifying material to pass it through the screen FAST! And when you work with Samscreen, your screens will be delivered FASTER too!

Screen Smarter

Screen Smarter

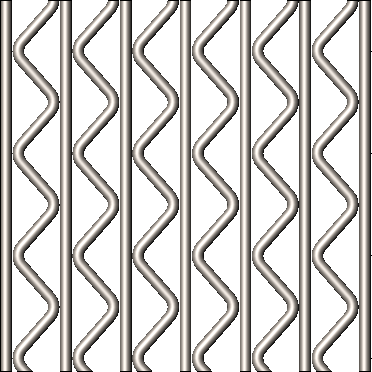

A screen so smart that it can clean itself while accurately producing an in-spec product! In much the same way as a piano or harp wire screen, the beauty of the MAX Kleen design is in its wire harmonics. The individually crimped (non-woven) MAX Kleen screen wires, are bound only by urethane cross strips, allowing each wire to vibrate independently, creating a fluid, dynamic screen surface that effortlessly cleans itself by never allowing material to bridge from wire to wire. When this innovative self cleaning action is combined with 6 unique wire patterns – designed to maximize open area for a variety of product specs – it amounts to the smartest screening solution for just about any application!

MAX Kleen is designed SMARTER – effortlessly cleaning itself to maintain maximum open area, while producing an in-spec product!

Screen Tougher

Screen Tougher

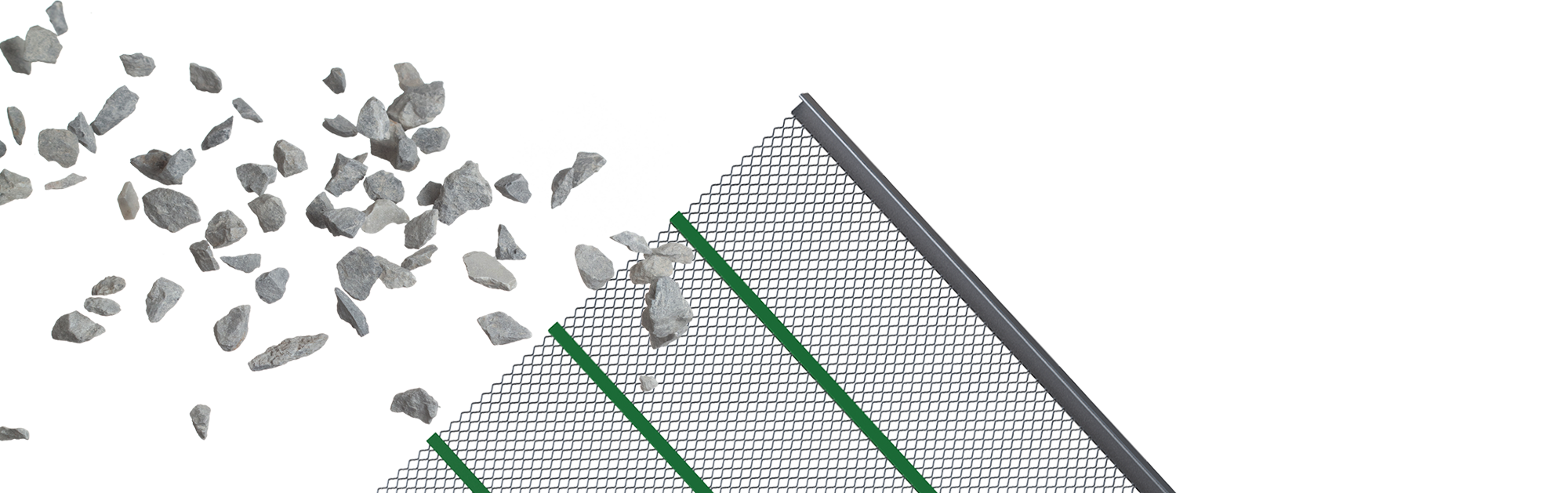

High quality domestic raw materials, a 100% North American supply base, and a rigorous multi-inspection quality process, means you get a screen that is as tough as the industry it serves! Over our 30 years in business, Samscreen has built a reputation for high quality American manufacturing and there is no better example of our relentless pursuit of excellence and screening innovation than our MAX Kleen self cleaning product line. Every MAX Kleen is constructed using only ASTM certified domestic steel wire, graded for the toughest applications, bound by one-piece molded urethane cross strips that are engineered to prevent delamination while allowing high wire vibration and creating a barrier between bucker bars and screen wires. The flat, non-woven MAX Kleen design also eliminates vulnerable high points, resulting in a tougher screen that wears up to 40% longer than woven wire!

100% North American raw materials, 100% US manufacturing, and rigorous quality standards = a screen that performs better and lasts longer… up to 40% longer than woven wire!

A MAX Kleen™

For every job

A MAX Kleen™

For every job

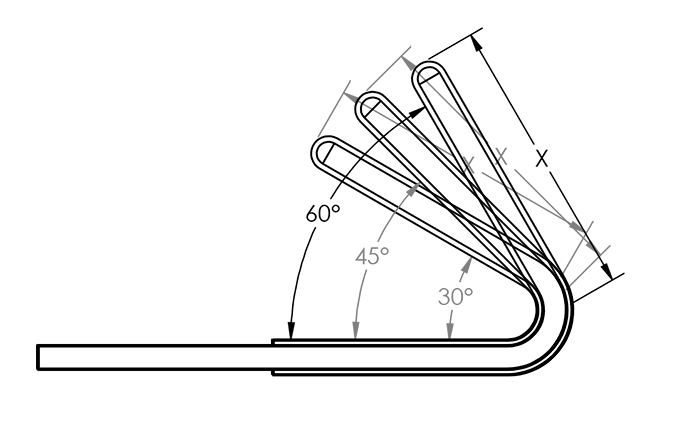

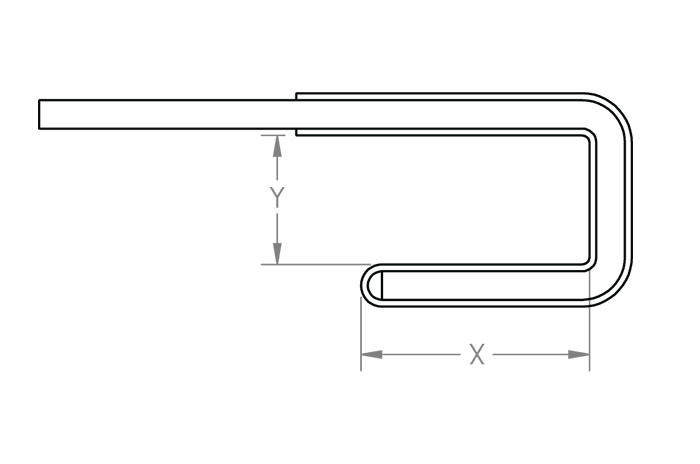

Available Hook Types

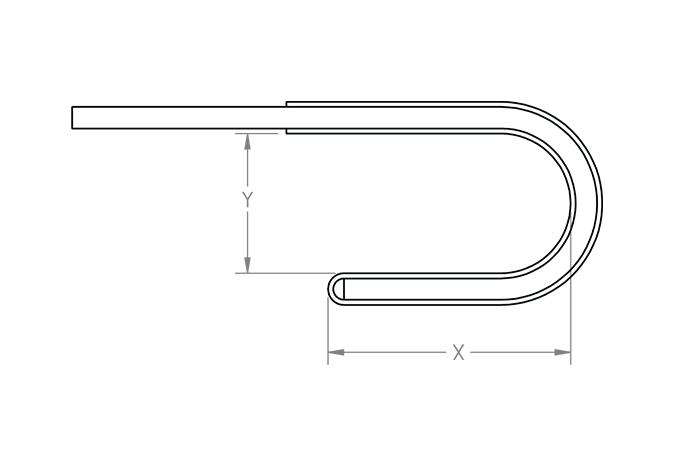

The hooks shown below are examples of common types, however, the hook shape, as well as the backleg and throat dimensions, can be customized for any machine.

30°- 60° Hook

Common Side-Tension Hook Style

Square Hook

Common End-Tension Hook Style

U Hook

Common End-Tension Hook Style

Screen Configuration

Tips

Maximize open area & screening productivity, while balancing sizing requirements & wear life goals – by understanding the benefits and trade-offs of each self cleaning screen configuration option. Use the interactive configuration tool above to fine tune your screening performance.

Wire

Thickness

Balance your wear life and production goals by choosing the thinnest wire your material will allow.

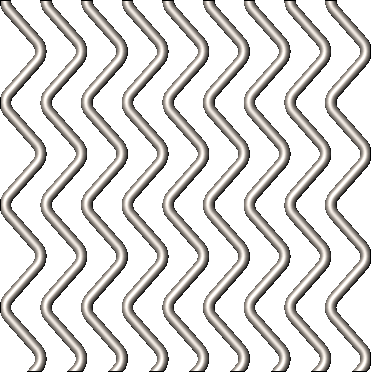

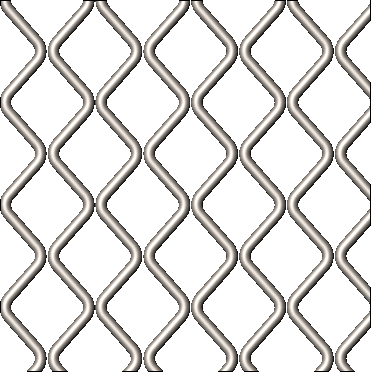

Wire Pattern

Most Open/Least Sizing

*Choose the screen pattern with the greatest level of open area allowable while still satisfying your sizing requirements

Greatest Sizing Control

Most Open / Least Sizing

*Choose the screen pattern with the greatest level of open area allowable while still satisfying your sizing requirements

Greatest Sizing Control

Wire Type

Carbon Wire

WHEN TO USE:

Screening heavy and/or abrasive material in dry conditions – Carbon Wire has greater impact and abrasion resistance than Stainless Steel Wire

WHEN NOT TO USE:

Screening corrosive or sticky materials – Carbon Wire will eventually pit and rust, compromising wear life and material thru-put

Vs.

Stainless Steel

WHEN TO USE:

Screening corrosive or sticky materials – Stainless Steel’s smooth non-rusting surface makes it ideal for wet, sticky, and corrosive environments, extending wear life and material thru-put

WHEN NOT TO USE:

Screening heavy and/or abrasive material in dry conditions – Carbon Wire has greater impact and abrasion resistance than Stainless Steel Wire

How Much Money

Are you leaving on your blinded over Woven Wire Screen?

Use the MAX Production Calculator below to find out

How Much Money

Are you leaving on your blinded over Woven Wire Screen?

Use the MAX Production Calculator below to find out

How Much Money

Are you leaving on your blinded over Woven Wire Screen?

Use the MAX Production Calculator below to find out