Economy & Quality

Economy

& Quality

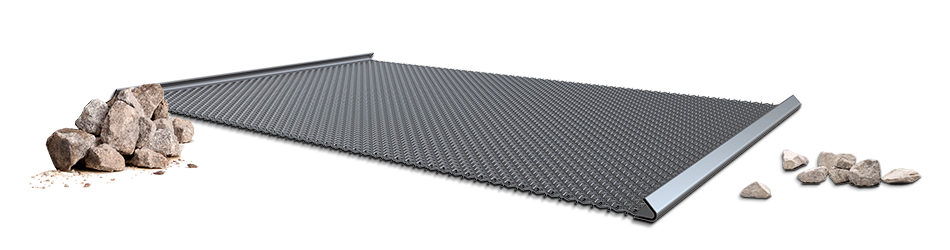

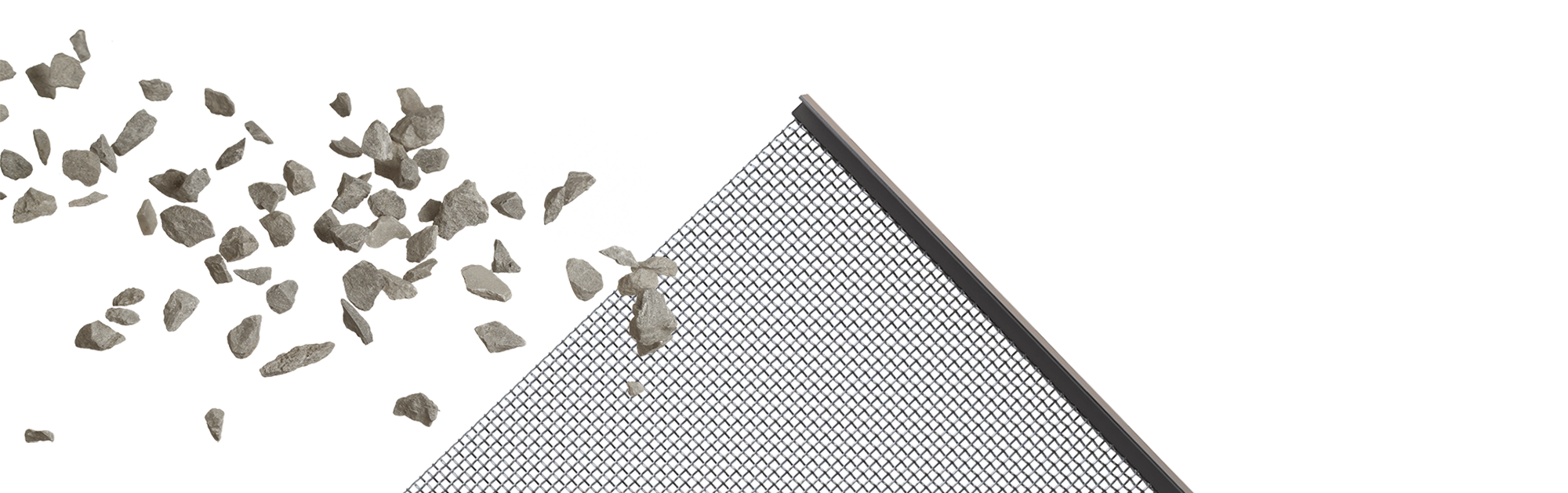

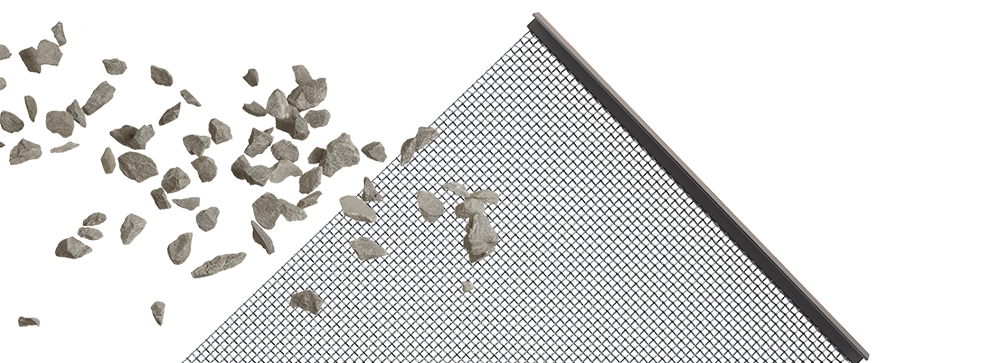

Samscreen offers high quality standard Woven Wire screens (also referred to as Woven Mesh or Woven Cloth screens) for applications in which blinding, pegging, matting and wear life are not an important concern. Manufactured in the USA, our Woven Wire screens are available in a wide variety of opening sizes and wire thicknesses to fit most common screening applications.

Convenience

Convenience

Keep it simple! Make one call, place one order, and get one invoice for all the different replacement screens you need for your varied applications. Samscreen is your one-stop-shop for Woven Wire, Perforated Plate/Punch Plate, Piano Wire, and MAX Kleen self cleaning screens, as well as Crusher Cones, Jaws, Bars, and Machined Wear Liners.

Get it Fast!

Get it Fast!

As the industry leader in fast turn times, Samscreen will make sure your Woven Wire screens are in your hands exactly when you need them!

Standard Woven Mesh

For many common applications

Woven Wire

- Low Cost

- Suitable for many Applications

- Fits any Machine

- Stores Easily

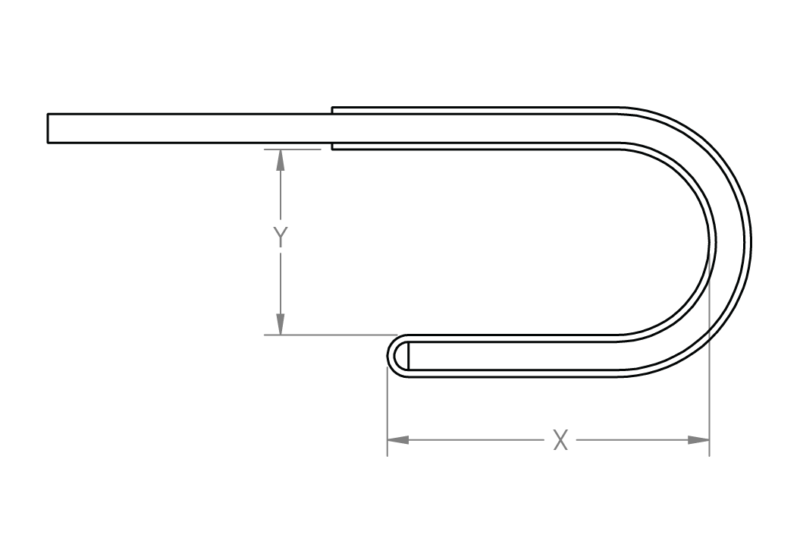

Typical End-Tension U Hook

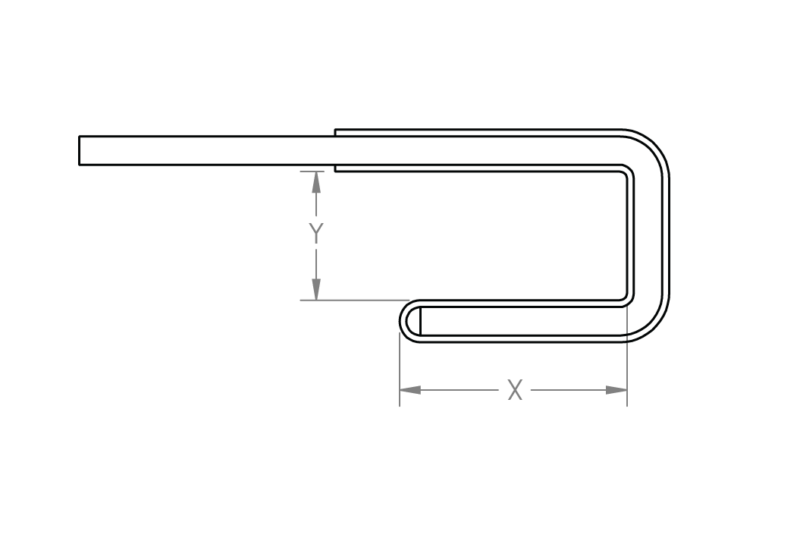

Typical End-Tension Square Hook

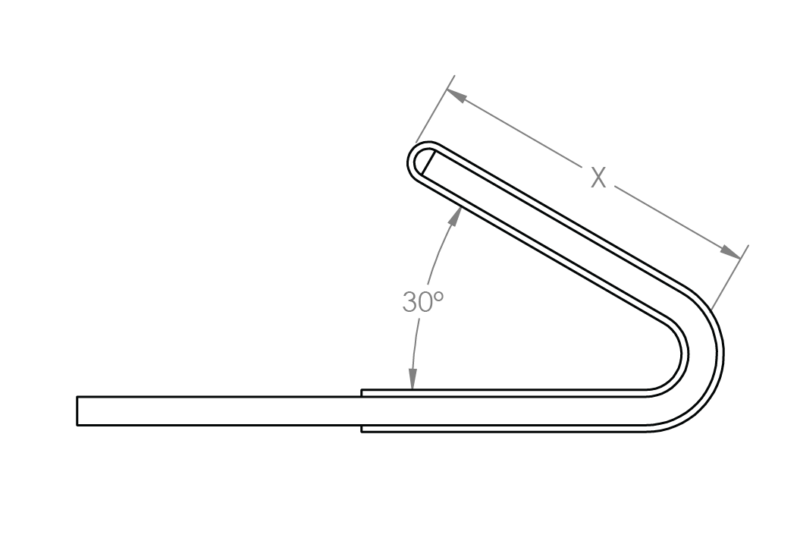

Typical Side-Tension 30° Hook

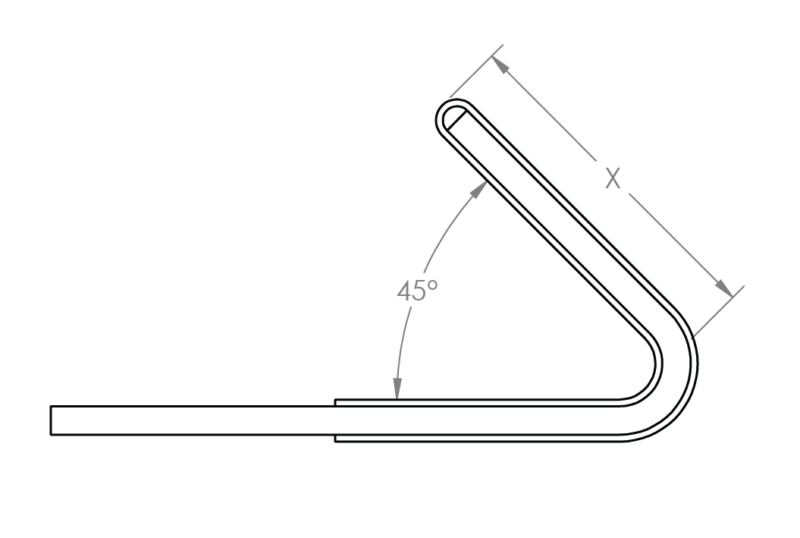

Typical Side-Tension 45° Hook

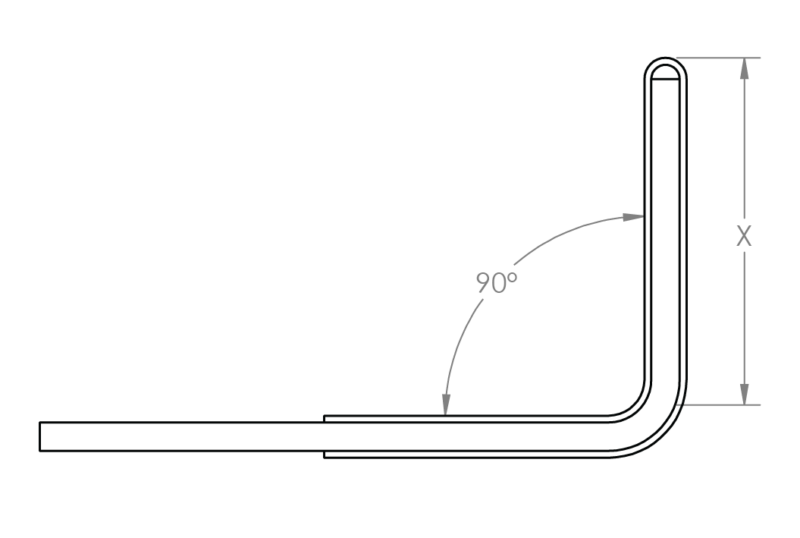

Typical Side-Tension 90° Hook

*Don’t see a hook that fits your machine? Speak to a Customer Service Rep to order a custom hook type.

| Opening Size Range | Wire Thickness Range |

|---|---|

| 1/8″ to 7″ | .063″ to .750″ |

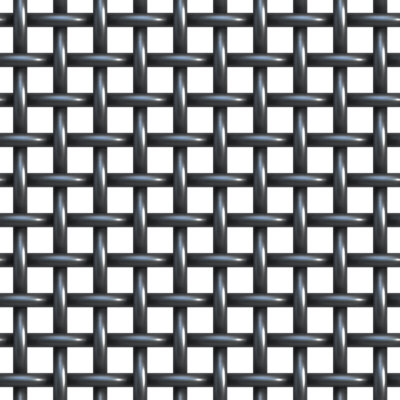

Oil Tempered Steel

High Strength Wire that resists premature breakage.

Very hard surface with softer core allows oil tempered wire to stand up well to impact and abrasion.

Prone to rust in corrosive environments.

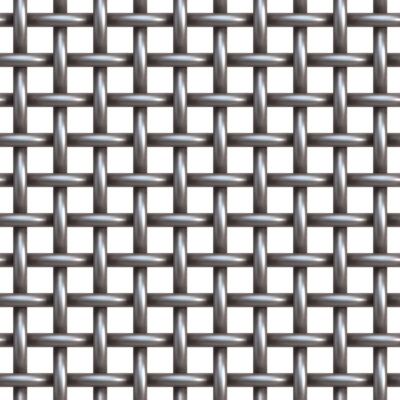

High Carbon Steel

High Strength Wire that wears consistently throughout its lifetime.

Through hardening creates a very hard wire with great wear consistency.

Prone to rust in corrosive environments.

Stainless Steel

Smooth stainless steel wire performs well in corrosive environments, resisting rust and preventing sticky material from clinging to wires.

Less impact and abrasion resistant than High Carbon and Oil Tempered Steel.

Is it Time

To Upgrade?

A Woven Wire screen is a solid economical choice for many types of low complexity material. However, when screening conditions get tricky, there are often better options. If your screening productivity is being impacted by pegging, matting, blinding or excessive wear, a low cost Woven Wire screen is likely not providing your operation with the best value. A higher performing screen, even if it comes at a slightly higher cost, can pay for itself quickly with increased production!

Check the common scenarios below to see if your screening operation is in need of a productivity upgrade!

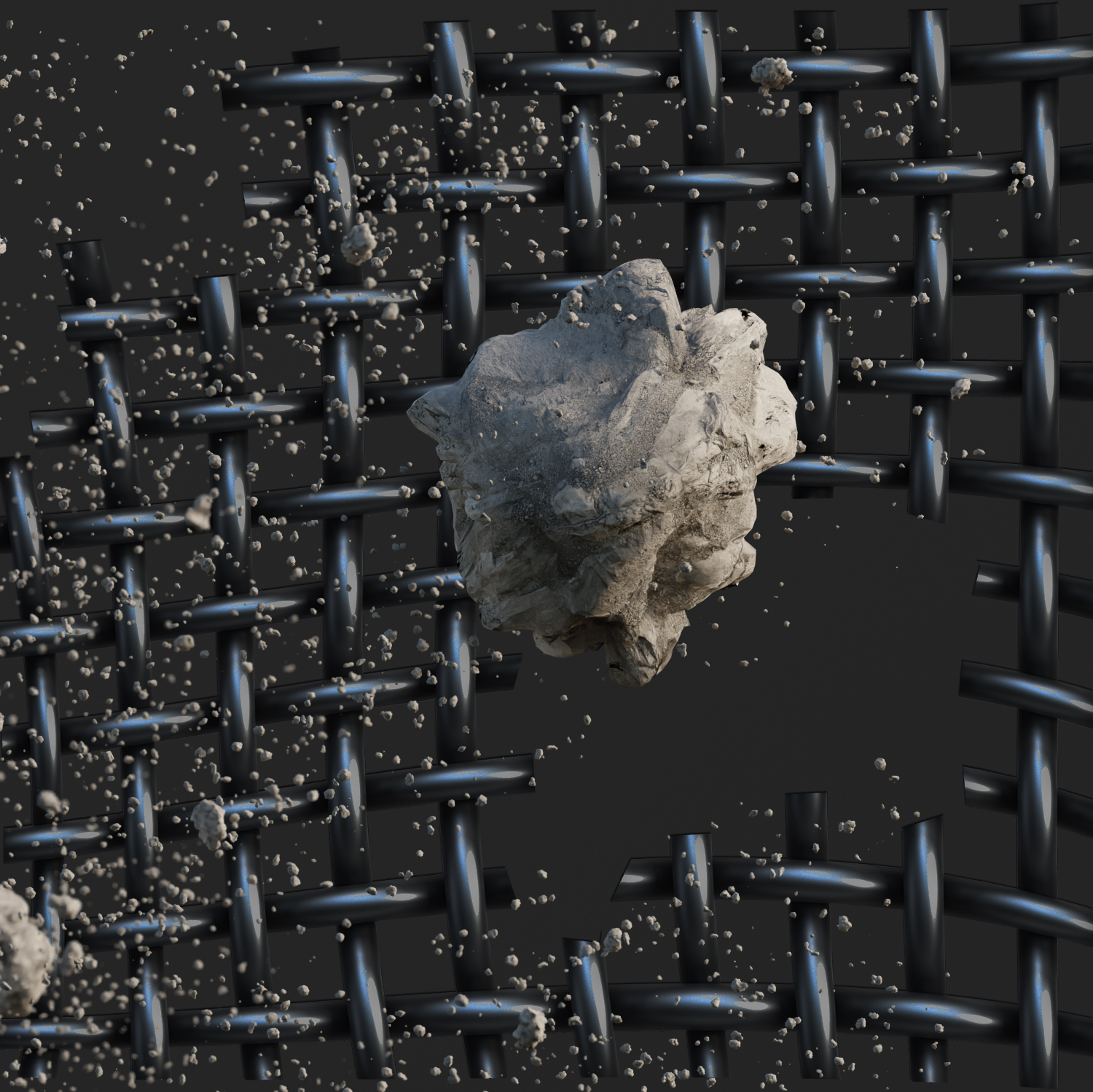

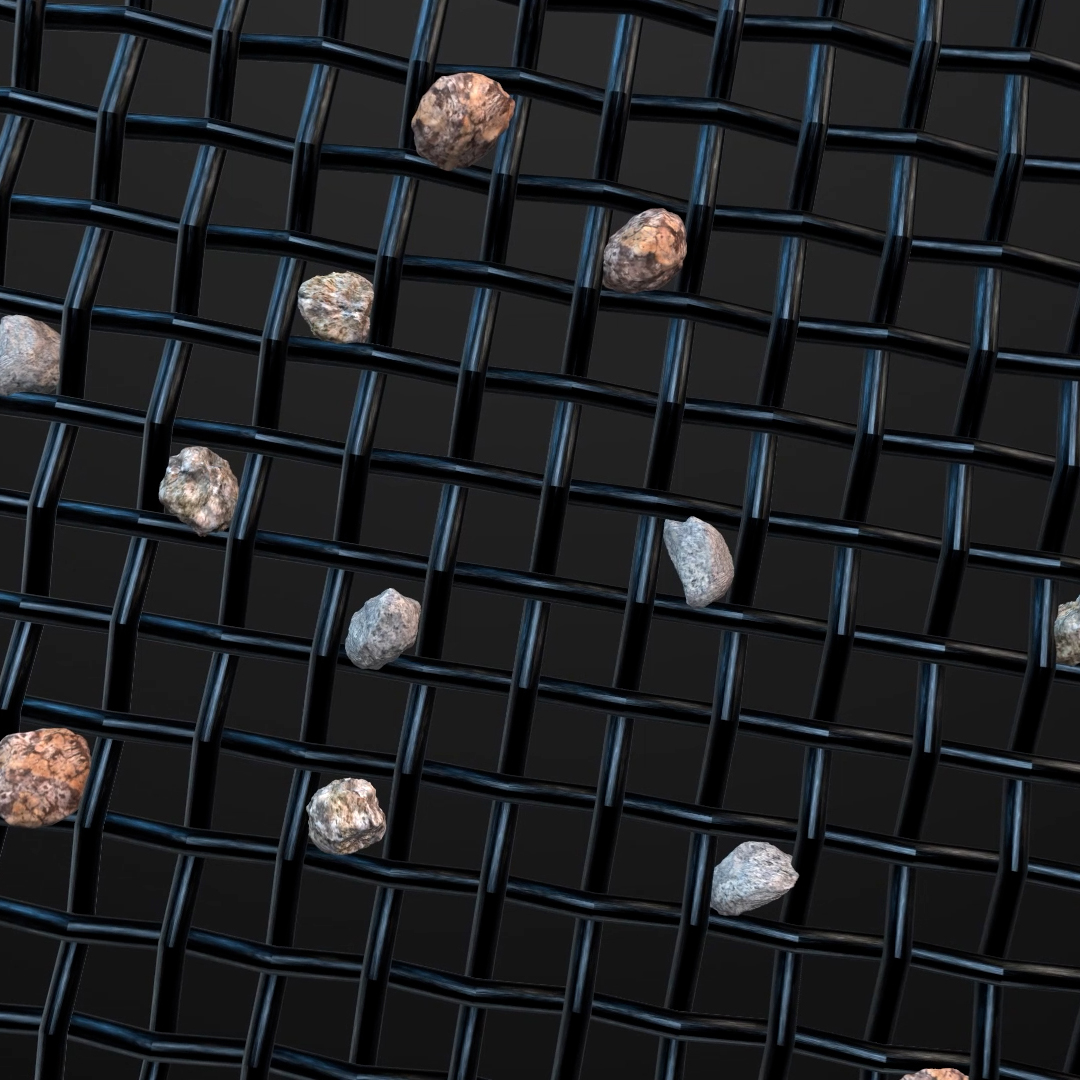

Pegging

Does your Woven Wire screen look like this halfway through the day? If you’re losing open area, you’re losing money! And, don’t forget about that hour at the end of the day when you have to shut down your machine and pay one of your guys to climb onto the screen to clear it by hand – that’s an expensive hour!

Material with a tendency to peg, calls for an efficient, longer wearing, self cleaning MAX Kleen screen!

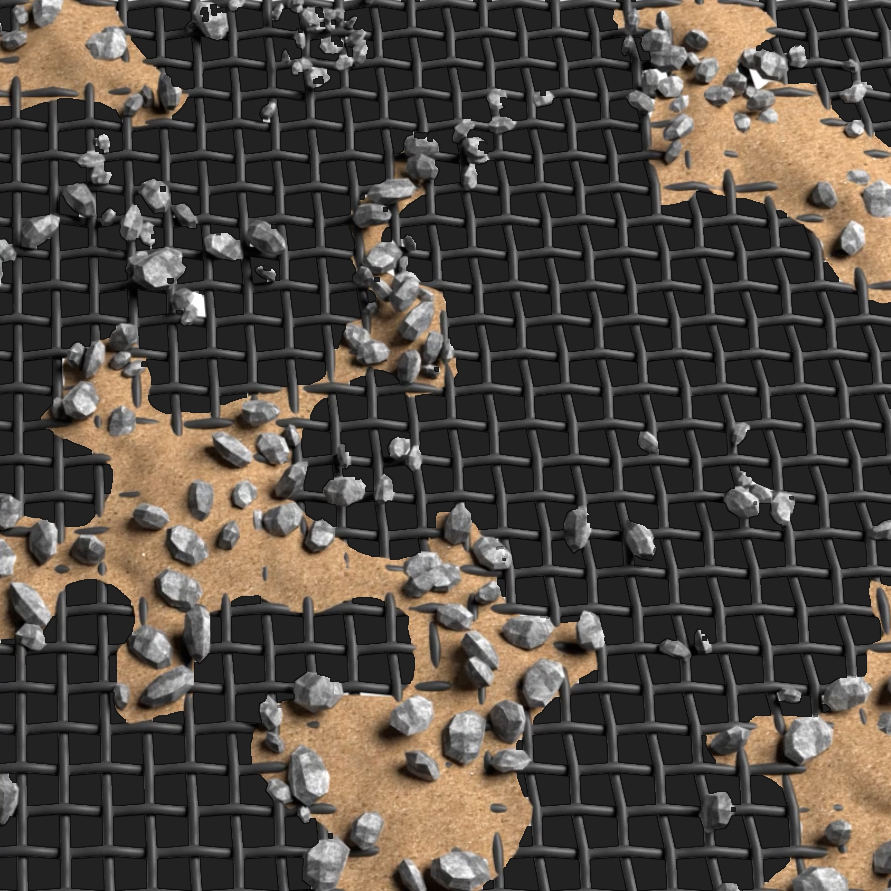

Blinding

Does your Standard Woven Wire or Long Slot Woven Wire screen continuously blind over to the point it looks like this all the time? If you’re losing open area, you’re losing money! In serious blinding situations you may be paying your guys to clean off the screen multiple times a day – that gets expensive fast!

Sticky, clumpy material with a tendency to blind and mat over calls for a high cutting action Piano Wire screen or self cleaning MAX Kleen screen!

Excessive Wear

Are you wearing through your Woven Wire screens too quickly? Unexpected screen failure is disruptive and costly. And, don’t forget about all the time spent removing and replacing your screens – that’s production time you’re using and two guys you’re paying to do it!

Is high knuckle wear causing sudden wire breakage? The flat crimped design of our self cleaning MAX Kleen screen’s resist wire breakage far better than most standard Woven Wire screens – often lasting 40% longer in the field!

Is high impact and/or abrasive material causing total screen failure? Get 6-10X the wear life with a high performance MAXWEAR Perforated Plate screen! See what America’s toughest steel can do for your operation.